SPP Process Technology Systems: Evolution, Capabilities, and Impact on the Semiconductor Industry

The semiconductor industry is built on continuous innovation, precision engineering, and highly specialised manufacturing systems. One name that frequently appears in historical and technical discussions of advanced semiconductor equipment is SPP Process Technology Systems. Although the name itself was used for a relatively short period, its technological legacy, organisational structure, and influence continue to shape modern semiconductor fabrication. This article provides an in-depth, end-to-end exploration of SPP Process Technology Systems, covering its origins, strategic purpose, core technologies, industry role, and long-term significance. The discussion is structured step by step with clear headings and concludes with a comprehensive summary.

Understanding SPP Process Technology Systems

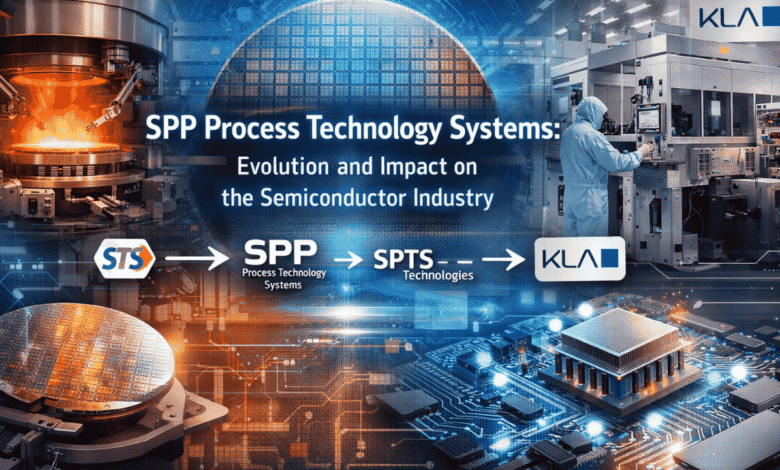

SPP Process Technology Systems refers to a semiconductor equipment organisation that emerged from strategic consolidation within the global semiconductor supply chain. The name is most closely associated with a period when Sumitomo Precision Products reorganised and integrated advanced semiconductor process technologies under a unified operational structure.

Rather than being a consumer-facing brand, SPP Process Technology Systems served as a technology and manufacturing backbone, focused on delivering high-precision tools to semiconductor foundries, integrated device manufacturers (IDMs), and MEMS producers.

Corporate Origins of SPP Process Technology Systems

The roots of SPP Process Technology Systems lie in the strategic expansion of Sumitomo Precision Products, a Japanese engineering firm with deep expertise in aerospace, precision mechanics, and advanced manufacturing.

As the semiconductor industry evolved in the late 2000s, Sumitomo recognised the growing demand for:

- Advanced plasma etching technologies

- High-aspect-ratio silicon processing

- MEMS and power device manufacturing solutions

To address this demand, Sumitomo consolidated semiconductor equipment assets, including technology lines historically associated with Surface Technology Systems (STS) and Aviza. This consolidation led to the establishment of SPP Process Technology Systems as a dedicated semiconductor equipment entity.

Strategic Purpose Behind SPP Process Technology Systems

The creation of SPP Process Technology Systems was not merely a rebranding exercise. It served several strategic goals:

- Technology Integration

Bringing together plasma etch, deposition, and thermal processing capabilities under one organisational umbrella. - Operational Focus

Allowing semiconductor equipment development to operate independently from Sumitomo’s other industrial divisions. - Global Market Expansion

Strengthening presence in Europe, Asia, and North America while maintaining engineering depth in the United Kingdom. - Preparation for Future Investment

Structuring the company in a way that allowed future acquisitions, management buyouts, or partnerships.

Core Technologies Developed by SPP Process Technology Systems

At its core, SPP Process Technology Systems specialises in advanced semiconductor manufacturing equipment. These tools were not mass-market products; they were mission-critical systems used in high-value fabrication environments.

Plasma Etching Systems

One of the most important technological areas was plasma etching, particularly deep reactive-ion etching (DRIE). These systems enabled:

- High-aspect-ratio silicon etching

- Precise vertical sidewalls

- Consistent wafer-to-wafer performance

Such capabilities are essential for MEMS sensors, power devices, and advanced logic components.

Deposition Technologies

SPP Process Technology Systems also supported various deposition techniques, allowing manufacturers to deposit thin films with:

- High uniformity

- Controlled thickness

- Strong material adhesion

These processes are critical in multilayer semiconductor architectures.

Thermal Processing Solutions

Thermal processing tools developed or supported under SPP Process Technology Systems enabled:

- Oxidation

- Annealing

- Stress control

Thermal precision is vital for maintaining device reliability and electrical performance.

Manufacturing and Engineering Footprint

A substantial segment of the engineering and manufacturing processes associated with SPP Process Technology Systems was based in the United Kingdom, particularly in Wales. This location had long been a hub for semiconductor equipment innovation, benefiting from:

- A skilled engineering workforce

- Strong links to European research institutions

- Proximity to global semiconductor customers

The UK base complemented Sumitomo’s Japanese manufacturing culture, blending precision engineering with agile innovation.

Role in MEMS and Power Semiconductor Growth

The rise of MEMS (Micro-Electro-Mechanical Systems) and power semiconductors significantly increased demand for the type of equipment developed under SPP Process Technology Systems.

Applications included:

- Automotive sensors

- Medical devices

- Industrial automation

- Consumer electronics

- Power management systems

MEMS fabrication, in particular, depends heavily on deep silicon etching and precise deposition—areas where SPP Process Technology Systems excelled.

Transition and Renaming of SPP Process Technology Systems

Although SPP Process Technology Systems was a formal name used for a limited time, its transition marked a pivotal moment. Following a management buyout and restructuring, the organisation became SPTS Technologies.

This transition allowed the company to:

- Operate with greater strategic independence

- Attract private investment

- Accelerate product development

Importantly, the technological DNA of SPP Process Technology Systems remained intact and continued under the SPTS Technologies name.

Long-Term Industry Influence

Even after the name SPP Process Technology Systems was phased out, its impact persisted through:

- Continued use of its equipment platforms

- Ongoing customer relationships

- Intellectual property and engineering expertise

Eventually, SPTS Technologies became part of KLA, further embedding SPP Process Technology Systems’ legacy within one of the world’s leading semiconductor process control ecosystems.

Why SPP Process Technology Systems Still Matter Today

From an industry and SEO perspective, SPP Process Technology Systems remains a relevant keyword because:

- It appears in historical corporate records

- It is referenced in legacy equipment documentation

- Customers still operate tools originally developed under that name

- Researchers and analysts trace technology lineage through it

Understanding this name helps clarify how modern semiconductor manufacturing capabilities evolved.

Conclusion: The Enduring Legacy of SPP Process Technology Systems

SPP Process Technology Systems represents more than a transitional corporate name—it symbolises a critical phase in the evolution of advanced semiconductor manufacturing technology. Formed to unify cutting-edge plasma etching, deposition, and thermal processing systems, it played a key role in supporting the rapid growth of MEMS, power devices, and advanced semiconductor architectures.

You May Also Read: Edge Banding Machine: Complete Guide, Types, Features, and Buying Tips (2025)