Edge Banding Machine: Complete Guide, Types, Features, and Buying Tips (2025)

An edge banding machine is one of the most essential machines in modern woodworking and furniture manufacturing. It enhances the durability, appearance, and value of furniture by sealing exposed board edges with a protective and decorative strip. From small workshops to large industrial factories, edge banders play a vital role in producing professional-grade furniture. In this detailed guide, you’ll learn everything about edge banding machines — how they work, types, features, applications, pricing, and how to choose the right one for your business.

What Is an Edge Banding Machine?

An edge banding machine is woodworking equipment designed to apply a narrow strip of material (edge banding) to the exposed edges of panels such as plywood, MDF, particle board, or blockboard.

The machine bonds edging material using hot-melt adhesive (EVA or PUR) and trims, flushes, and polishes the edges to give a smooth, finished appearance.

Why Edge Banding Is Important

- Improves aesthetics

- Protects boards from moisture & chipping

- Increases durability and lifespan

- Enhances professional finish

- Adds value to furniture

How Does an Edge Banding Machine Work?

A typical edge banding process includes the following steps:

- Panel Feeding – The Board is fed manually or automatically.

- Glue Application – Hot-melt adhesive is applied to the panel edge.

- Edge Feeding & Pressing – Edge tape is pressed onto the panel.

- End Cutting – Excess edging is trimmed from the front and rear.

- Top & Bottom Trimming – Excess thickness removed.

- Corner Rounding – Smooth rounded edges.

- Scraping & Buffing – Final polishing for a seamless finish.

Advanced machines perform all steps automatically in one pass.

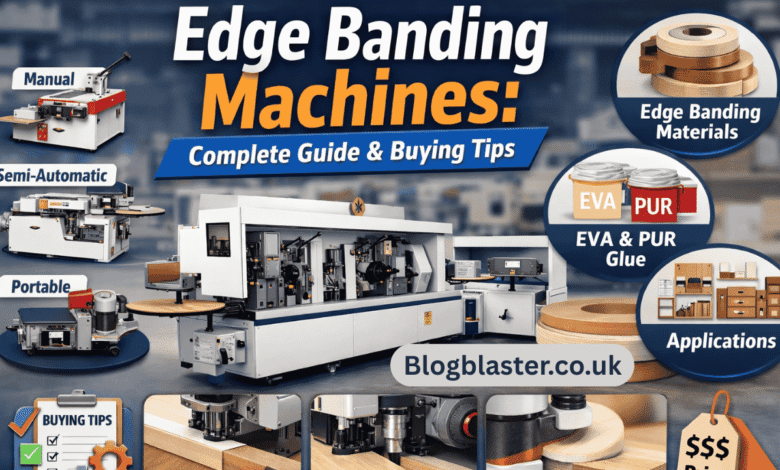

Types of Edge Banding Machines

Manual Edge Banding Machine

Best for small workshops or DIY users.

Features:

- Manual feeding

- Low cost

- Portable

- Suitable for small workloads

Limitations:

- Slower production

- Lower finish quality

- Operator-dependent accuracy

Semi-Automatic Edge Banding Machine

Ideal for small to medium furniture factories.

Features:

- Automatic glue application

- Manual board feeding

- Trimming and buffing units

- Moderate production speed

Advantages:

- Affordable

- Better finish than manual

- Easy to operate

Automatic Edge Banding Machine

Used in industrial furniture manufacturing.

Features:

- Fully automatic operation

- High-speed processing

- Multi-function stations

- Excellent finishing quality

Common Functions:

- Pre-milling

- Gluing

- End trimming

- Fine trimming

- Corner rounding

- Scraping

- Polishin

Portable / Handheld Edge Banding Machine

Best for on-site jobs or small repairs.

Features:

- Lightweight

- Portable

- Ideal for curved edges

- Low power consumption

Limitations:

- Not suitable for mass production

Types of Edge Banding Materials

| PVC | Most common, durable, flexible |

| ABS | Eco-friendly, impact resistant |

| Acrylic | High-gloss finish |

| Wood veneer | Natural appearance |

| Melamine | Budget-friendly |

| Solid wood | Premium furniture |

Glue Types Used in Edge Banding Machines

EVA (Ethylene Vinyl Acetate)

- Most commonly used

- Cost-effective

- Easy maintenance

- Lower heat resistance

PUR (Polyurethane Reactive)

- Stronger bonding

- Waterproof

- Heat resistant

- Ideal for premium furniture

- Higher cost

Key Specifications to Consider

| Edge thickness | 0.4 – 3 mm |

| Panel thickness | 10 – 60 mm |

| Feed speed | 5 – 25 m/min |

| Glue temperature | 160–200°C |

| Power | 3 – 15 kW |

| Air pressure | 0.6 – 0.8 MPa |

Applications of Edge Banding Machines

- Modular furniture

- Kitchen cabinets

- Office furniture

- Wardrobes

- Wooden doors

- Hotel & commercial furniture

- Interior fit-outs

Advantages of Using an Edge Banding Machine

✔ Professional finish

✔ Increased production speed

✔ Stronger panel protection

✔ Reduced material wastage

✔ Consistent quality

✔ Improved resale value

Edge Banding Machine Price Range

| Manual | $500 – $1,500 |

| Portable | $800 – $2,500 |

| Semi-automatic | $3,000 – $7,000 |

| Automatic | $8,000 – $35,000+ |

| Industrial CNC | $40,000+ |

Prices vary depending on brand, country, features, and automation level.

Top Edge Banding Machine Brands

- Biesse

- HOMAG

- SCM

- HOLZ-HER

- Felder

- Nanxing

- KDT

- IMA

Chinese manufacturers offer excellent value for money, while European brands dominate the premium segment.

Guidelines for Selecting the Appropriate Edge Banding Machine

Ask Yourself:

- What is your daily production volume?

- What edge thickness do you use?

- EVA or PUR glue?

- Manual or automatic operation?

- Available floor space?

- Budget range?

Recommended Selection Guide:

- Small workshop → Manual or semi-auto

- Medium factory → Automatic (basic)

- Large manufacturer → Fully automatic with pre-milling & PUR

Maintenance Tips

- Clean the glue pot daily

- Use the recommended glue type

- Check pressure rollers regularly

- Clean trimming blades

- Keep dust extraction functional

- Perform scheduled lubrication

Good maintenance increases machine life by 30–40%.

Future Trends in Edge Banding Machines

- Laser edge banding technology

- Zero-joint systems

- AI-based diagnostics

- Energy-efficient heating

- Automated glue change systems

- Industry 4.0 integration

Frequently Asked Questions (FAQs)

What is the best edge banding machine for small workshops?

A semi-automatic or portable edge banding machine is ideal for small shops.

Which glue is better: EVA or PUR?

PUR offers stronger bonding and water resistance, while EVA is cheaper and easier to maintain.

How long does an edge banding machine last?

With proper maintenance, it has an expected lifespan of 8–15 years, depending on usage.

Can one machine handle different edge thicknesses?

Yes, most modern machines support 0.4–3 mm edges.

Conclusion

An edge banding machine is a critical investment for any woodworking or furniture manufacturing business. Whether you’re running a small carpentry shop or a large-scale factory, choosing the right machine improves productivity, finish quality, and customer satisfaction.

You May Also Read: DK380C4.0-H8: Features, Specifications, and Industrial Applications