How to Choose the Right Electronics Manufacturer in Australia

Choosing the wrong electronics partner can quietly kill a great product idea. Delays, quality issues, poor communication and unexpected costs all add up fast—especially once you move from small prototypes to real production volumes.

The good news is that Australia has a solid ecosystem of manufacturers who can support everything from early-stage development to long-term production. The challenge is knowing how to evaluate them properly before you commit.

This guide walks through the key factors to consider when selecting an electronics manufacturer in Australia, so you can build a reliable relationship instead of an expensive headache.

Clarify Your Needs Before You Start Shortlisting

A lot of frustration comes from starting conversations with only a rough idea of what you need. Before you reach out to potential partners, get clear on a few basics:

- What stage you’re at: concept, prototyping, pre-production, or established product

- Your expected volumes: small batches, regular low–mid runs, or high volume

- Any compliance or industry-specific requirements (medical, defence, mining, etc.)

- Whether you need design support, or just manufacturing and assembly

When you know these details, it’s easier to filter out manufacturers who aren’t a good fit and avoid wasting time on conversations that won’t go anywhere.

Look for Local Expertise and Industry Experience

Not all manufacturers are strong in the same areas. Some specialise in industrial controls, others in consumer electronics, IoT devices, automotive or specialised instrumentation. The closer your project is to their sweet spot, the better your outcomes will usually be.

Explore their past work, case studies and industries served. If your product needs to handle vibration, harsh temperatures or strict safety standards, you want a partner who already understands those constraints—not one learning on your project for the first time.

A company like Precision Electronics, for example, brings deep experience in Australian and international standards, which can significantly shorten the path from prototype to compliant, market-ready product.

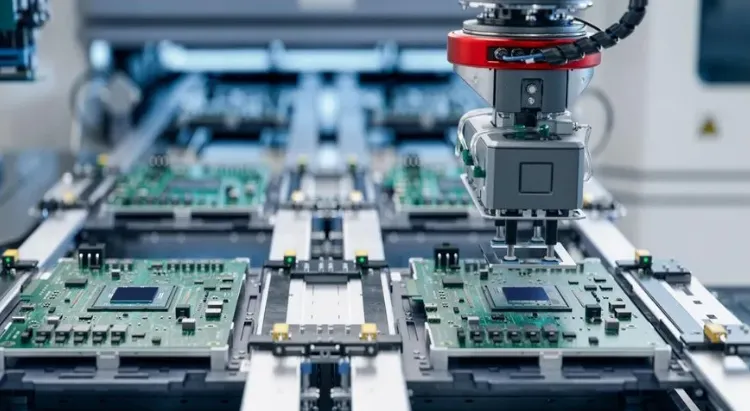

Assess Technical Capability and Equipment

The quality and consistency of your boards depend heavily on the manufacturer’s equipment and process control. When you review potential partners, look at:

- The types of assembly lines they operate (SMT, through-hole, mixed technology)

- Their ability to handle fine-pitch components, BGAs, high-density designs

- Whether they use modern inspection tools such as AOI and X-ray

- Their approach to testing: in-circuit testing, functional testing, burn-in, etc.

Ask specific questions about reflow profiles, process monitoring, ESD control and cleaning processes. Manufacturers that can answer these confidently are usually more disciplined in their production.

Check Their Approach to Quality and Traceability

Strong process discipline is just as important as the machines themselves. A reliable partner should be able to explain:

- Their quality management system (for example, ISO certifications)

- How they handle non-conformances and corrective actions

- How components and boards are traced from incoming stock to finished goods

- What documentation you will receive with each batch (test reports, lot tracking, etc.)

Traceability is particularly important if you work in regulated or safety-critical markets. If you ever need to investigate a field failure, you’ll want to know exactly which batch, components and processes were involved.

Evaluate Communication and Engineering Support

Even with a strong design, there will be questions, tweaks and unexpected issues. The way your manufacturer communicates can make or break a project.

Pay attention to how responsive they are during early conversations. Do they ask detailed questions about your design and end use? Are they willing to suggest design-for-manufacture (DFM) improvements? Are timelines and costs explained clearly?

A good partner will flag potential problems early, rather than quietly pushing a design through and hoping for the best. That collaborative mindset is often more important than shaving a few cents off unit cost.

Consider Their PCB Assembly Capabilities

For most projects, printed circuit board assembly is the heart of the build. This is where component sourcing, placement, soldering and testing all come together.

When evaluating this part of their offering, look at:

- Whether they can source components reliably or prefer you to supply them

- Lead times for common parts and how they manage shortages or obsolescence

- Minimum and maximum order quantities and their flexibility on small prototype runs

- Their experience with complex assemblies, such as multi-layer boards or mixed technologies

A strong PCB assembly capability means fewer surprises in yield, better consistency from batch to batch, and a smoother path as your volumes grow.

Think About Scalability and Long-Term Fit

You’re not just choosing a supplier for the next two months—you’re potentially choosing a partner for years. It’s worth asking:

- Can they scale with you if volumes double or triple?

- Do they have room on their lines for your projected demand?

- Are they interested in a long-term relationship, or only in once-off jobs?

Look for manufacturers who are open about their capacity, willing to plan ahead and keen to grow with your business. That alignment makes it easier to negotiate better terms as your partnership deepens.

Don’t Ignore Total Cost of Ownership

Unit price matters, but it’s only part of the story. Cheap manufacturing that leads to high failure rates, frequent redesigns or missed launch windows quickly becomes the expensive option.

When comparing quotes, consider:

- Yield and rework rates

- Time your engineering team spends resolving issues

- Warranty claims and returns

- Shipping, customs, and delays if you use offshore providers

Local partners who invest in quality, communication and engineering support often deliver better total value, even if their headline price per board is slightly higher.

Take a Structured Approach to Selection

Finally, treat manufacturer selection as a structured process, not a quick purchase. Shortlist a few candidates, share the same information and questions with each, and document their answers. If possible, visit their facilities—seeing production lines in person is invaluable.

By evaluating technical capability, quality systems, communication, scalability and total cost together, you’ll be in a much stronger position to choose an electronics manufacturing partner that can support your product from concept through to long-term production.